Spinal Instrumentation

Spinal Instrumentation

Internal spinal fixation devices are typically employed as mechanical adjuncts to provide initial stability and surgical correction. Despite thirty years of clinical use and extensive research into the in vitro performance of such devices, severe clinical problems remain regarding the suboptimal performance of fixation devices in providing an optimal mechanical environment to enhance bone healing, causing malunion of bone fusion mass and loss of surgical correction, spinal pathology consequent to the implantation of the instrumentation, and the frank instrumentation failure in osteoporotic in the metastatic spine.

-

Spine fixation system design.

Current Research

1. Effect of screw-bone interface integrity on its pullout performance.

With age, vertebral bone demonstrates significant changes in architecture and its mechanical strength. As a result, transpedicular screws loosening and failure in osteopenic vertebral bone is a common clinical problem and presents great difficulties when attempting surgical revision due to the poor quality and availability of bone within the vertebrae and the proximity of neural elements. Achieving a strong mechanical coupling between the screw and the bone is paramount for the success of either the applied surgical correction or for promoting spine fusion. In collaboration with the Harvard John A., Paulson School of Engineering and Applied Sciences, Cambridge and the neurosurgery department at Brigham and Women's Hospital, Boston, we are investigating the use of dynamic characterization methods to quantify the effect of screw-bone interface on the pedicular screw's pullout performance.

Previous research

1. Biomechanics of spinal fixation systems [1, 2]:

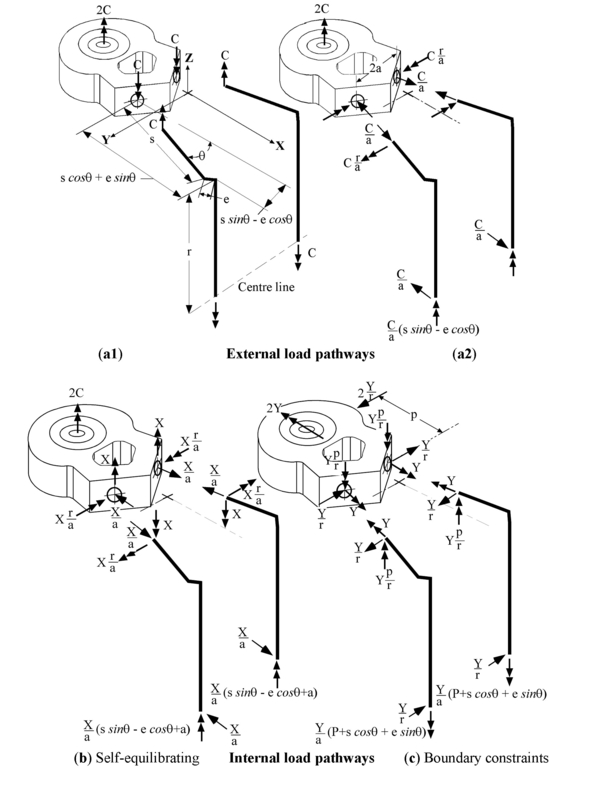

This work investigated the role of the design of spinal fixation systems in affecting the instrumented spine structural response to complex functional loads. Both the change in clamp tightening torque and the inclusion of transverse stiffening members significantly altered the structural behavior of the instrumented spine in response to bending and torsional moments [1]. Data obtained from strain gauges mounted on the fixation system led to the identification of four distinct load response pathways underlying the overall response of the fixator and the effect of the geometry and mode of assemblage on these pathways [2]. Analytical models, developed to provide insight into the role of the external and internal load response pathways in the response of the fixator, showed excellent agreement with the experimental results.

|

|

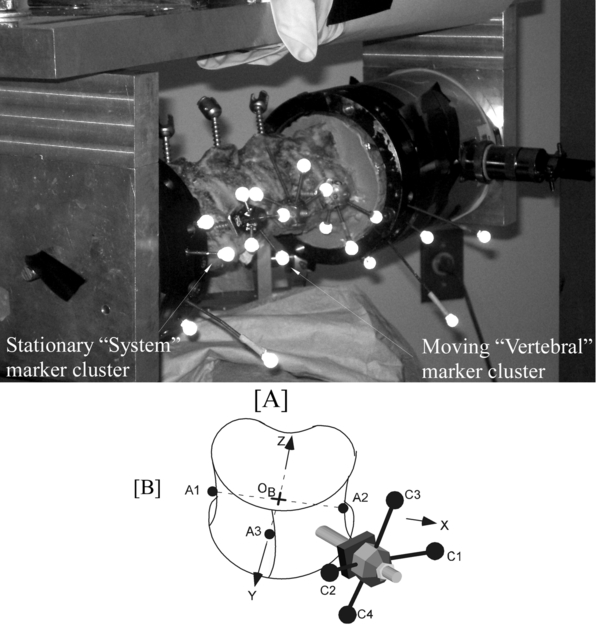

| Figure 1.Schematic diagrams of the distribution of bending and torsion underlying the response of the fixator under applied torque as a result of applied loading and internal load response pathways [2] | Figure 2. Illustration of the spine instrumented with optical markers used to measure the translational and rotational motions of the vertebrae under applied moments [A]. The cluster of optical markers(C1..C4) is used to identify the vertebral translation and rotation about its anatomical axes (A1..A3), [B]. |

2. Constructs for terminating dual-rod instrumentation [4]:

This study compared the mechanical behavior of five different constructs used to terminate dual-rod, posterior spinal instrumentation on the ability of short spinal constructs to resist forward flexion moment and prevent the occurrence of distal screw pullout.

3. Effect of screw thread on pullout performance [3]:

A parametric study on the effects of the design of the Schanz screw thread parameters on the screw-bone interface strength under pullout testing. The study demonstrated complex inter-relationships between the different design parameters and the bone-screw interface failure, with both bone structure and material properties significantly affecting screw performance.

4. Effect of screw head design on the maintenance of vertebral derotation [5]:

This work applied a specialized testing construct and optical kinematic measurement at each instrumented vertebral level to investigate the efficacy of various methods to secure long-spinal constructs to prevent premature failure of the constructs due to screw-pull out and the effect of screw head design on the ability of spinal instrumentation to affect derotation of the spine.

Publications

- Alkalay RN, Sharpe D, Bader DL. The effects of the design and configuration on the biomechanical response of an internal spinal fixator. Proc Inst Mech Eng 1999;13:137-46. PMID: 10333685, DOI: 10.1243/0954411991534852

- Alkalay RN, Sharpe D, Bader DL. A biomechanical analysis of an instrumented spinal fixator under torsional loads. J Biomech 2005;38:865-76. PMID: 15713308, DOI: 10.1016/j.jbiomech.2004.04.029

- Alkalay RN, Bader DL. The effects of screw design parameters on the performance of transpedicular screws in vertebral bone under tensile loads: A parametric study. Clin. Biomech. 2009. PMID: 27879505, DOI: 10.1097/BSD.0b013e3182a03c70

- Sun E, Alkalay RN, Vader D, Snyder BD. Preventing distal pullout of posterior spine instrumentation in thoracic hyperkyphosis: A biomechanical analysis. J Spinal Disord. Tech., 2009: 22(4):270-277. PMID: 19494747, DOI: 10.1097/BSD.0b013e31816a6887

- Lam CF, Groff MW, Alkalay RN.The effect of screw head design on rod derotation in the correction of thoracolumbar spinal deformity: laboratory investigation. J Neurosurg Spine. 2013: 19(3):351-9. PMID: 23869406, DOI: 10.3171/2013.6.SPINE12655

2. Intervertebral cages: design considerations and preoperative planning.

Previous research

Effect of cage design on cage subsidence [5]:

In collaboration with Michael Groff MD, we investigated the effect of cage design, instrumentation strategies and site preparation methods on the incidence of cage subsidence in cadaveric vertebrae. Both cage design and assessment of bone mineral density affected the yield of the vertebral bone underneath the cage and progression of cage subsidence, independent of lumbar level. We aim to investigate the use of image-based techniques to assess whether interrogation of the volumetric distribution of bone at the intended surgical site and the degree of site preparation could be optimized to enhance the survival of the cage construct under dynamic loading conditions.

PMID: 21430566, DOI: 10.1097/BSD.0b013e31820ef778